Fuelab Offers Microscopic Fuel Filtration With Big Flow Capabilities

Fuel filters for high-performance or all-out racing have a greater duty than many consider. We’ve seen scores of racers using a strainer-style filter within a funnel at the track and calling that “good enough.” Today’s fuel pumps, electronic injectors, carburetors, sensors, and more continue to tighten their tolerances to achieve a better fuel feed to meet higher horsepower demands, and fuel filters need to step up their game to protect these components.

Flow Criteria for Filters

The overall flow of a fuel system is only as good as the combination of components and how they either feed or circulate your fuel supply. We outfitted the Project Rover Camaro with a pair of Fuelab in-line filters for our E85-fueled, electronic fuel injection system. Brian Paitz, President at Fuelab, provided some insight into the proper filtration of a racing or extreme performance fuel system.

“The one thing that I can’t stress enough when you’re setting up a fuel system is that you look at it as an entire system,” Paitz begins. “It goes beyond just a pump, it goes beyond the regulator — it also has a lot to do with your filters.”

Filter Sizing and Location

The success of feeding your engine for its peak fuel demands will depend greatly on two critical locations in your filtration: filtering the fuel before and after the fuel pump is the most effective layout. These two filtering points ensure your fuel system is optimized for flow — yet protected.

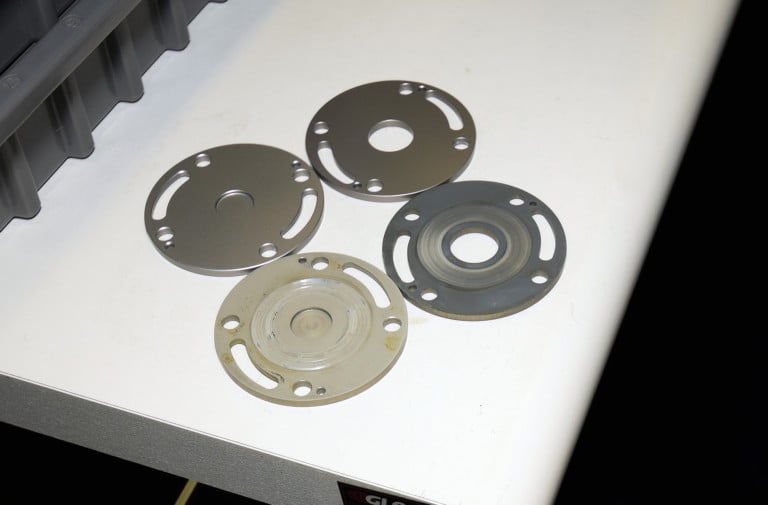

Fuelab offers a variety of filter choices in paper/cellulose, fiberglass, and stainless steel mesh filter media that best apply to your filter size and fuel type. While in their shop, they showed two scored fuel pump plates alongside originals that demonstrated the result of not using proper filters before and after your fuel pump.

Fundamentally, we spec’d out our in-tank fuel pump at 150 gallons per hour (GPH). With that, we researched the Fuelab filter GPH offerings and chose the 818 Series in-line fuel filters, which can handle 200 gph. These feature male 37-degree flared fitting end caps on both ends, and can be ordered with various size combinations across -6AN, -8AN, -10AN, or -12AN male inlets and outlets.

Paitz explains that you must choose filter sizing to prevent pressure drops. “You want to be sure you get a pump filter that can handle the fuel capacity leaving the pump,” he says. “You want to minimize pressure drop across the filter. Blowing 10 gallons per minute through a filter that has a -6AN inlet and outlet is going to create a pressure drop across that filter, potentially losing a couple of pounds of pressure.”

Our EFI system dictated our remaining hose sizes; it calls for a -8AN inlet hose and a -6AN return line. We took advantage of Fuelab’s unlimited combination of AN fittings at the filters’ inlet and outlet ports to plumb a -10AN filter inlet from our pump to a -8AN filter outlet towards our EFI system, and a -6AN filtered return to the tank.

Outside of our selection, Fuelab also offers filters in larger sizes. The 828 Series inline filters are the same diameter as the 818 filters we’re using, but hold a 5-inch-long filtering element compared to the 818 models’ 3-inch-long filter. The 828 Series supports 350 gph of flow.

Their new 868 PRO Series Extreme Flow inline fuel filters have a 10 GPM rating for maximum flow and minimal pressure drop. Wait, GPM? Yes, this filter will flow 10 gallons per minute with -10AN male inlets and outlets and a 5-inch diameter filtering element.

They do put the word “lab” in the company name at Fuelab for a reason: its extensive testing equipment helps to develop the highest internal flow characteristics to prevent low-pressure points within the filters. Their 3-inch fiberglass, 5-inch paper/cellulose, and 5-inch stainless steel filter media are shown.

Filtering Media and Fuel Type

Fuelab offers multiple choices of filter cartridges to insert into your filter cases. “We recommend that you use a filter with the 100-micron rating or finer before any performance type pump,” Paitz explains. “It’s super important to get the properly sized pre-filter before the fuel pump. This stainless filter element should only be used as a pre-filter for fuel pumps — it helps prevent pump cavitation with an extremely low-pressure drop.”

A finer element (lower numerical micron rating) is recommended directly following your fuel pump to protect injectors, carburetors, and other downstream components, such as fuel sensors. There is a variety of filter media choices; the deciding factor is your fuel type used.

A numerical rating describes a filter’s capabilities. For instance, a 100-micron filter will stop a particle as small as 100 microns. Our micro-fiberglass element offers extra protection by eliminating particles down to 6 microns in size. – Brian Paitz, Fuelab

Filter Media Choices

The Fuelab stainless steel filter is available in 40 and 100 micron filtration levels and is compatible with gas, diesel, ethanol, and methanol. In addition, the stainless filter is cleanable and does not necessarily require replacement for maintenance.

“Our 100-micron cellulose paper element is economical, and commonly used as a pre-pump filter element, but can only be used with gasoline and diesel fuels,” Paitz says. “Our most advanced filter is our micro-fiberglass element — it provides extra particle protection with improvements in filter efficiency. This disposable element is compatible with gas, diesel, ethanol, and methanol.”

The filter housing offers a threaded cap allowing access to the filter area. Paitz shows us a fiberglass media filter that did its job to filter E85 to the point of collapsing. He told us this customer did not replace his filter for over two years.

Our E85-fueled project Camaro has a recirculating fuel system that uses a return line to the in-tank pump. We installed Fuelab’s stainless-steel 100-micron filter before the tank’s return line inlet and their inline filter with a 6-micron fiberglass element directly following the pump’s output.

One curveball that Paitz cautioned with cellulose/paper filters is the use of oxygenated fuels. Even if you’re racing with gas or diesel, if that fuel is oxygenated, definitely choose the micro-fiberglass option.

If you’re using the stainless-steel screen filters at one or more points, cleaning and reusing these filters is reasonably easy. Scrubbing with carburetor cleaner, a catch pan, and compressed air will do the trick; we go a little further and use a parts-cleaning toothbrush and a small ultrasonic cleaner in our filter maintenance.

Another option is the check valve (arrow) integrated into the housing. This allows the benefits of your fuel system remaining pressurized when your fuel pump is not running. Their pumps, filters and regulators are anodized per military MIL-A-8625 with a high-tech laser etching of your product and serial number on the case.

It is wise to make sure you have spare O-rings from Fuelab in your tool box in case one is damaged during the disassembly of the filter housing. For paper/cellulose or fiberglass filters, there is no recleaning option. All replacement filters from Fuelab come with replacement fluorosilicone O-rings.

Additional Features

All Fuelab filters are machined from billet aluminum and finished with a fuel-durable anodizing per military specification MIL-A-8625 (Type II). They are available in a variety of anodized colors.

The filter housing is designed with machined internal radius points along the internal flow of the filter housing from inlet to outlet. These radiused provisions allow for minimal pressure drop in the fuel flow. An internal spring forces the filter against the downstream port of the housing to seal it; this causes the fuel to travel through the filter from the outside inward.

Inside, you can see the extensively developed flow radius corners that offer the best flow numbers. An internal spring forces the filter element over the exit port where all fuel travels from the outside of the media, inward for best flow. An outlet indicator is machined into the housing.

For Fuelab’s 848 and 858 series filters, there is an integrated check-valve option that allows your fuel system to maintain fuel pressure when the pump is dormant. The compact valve is located at the exit port of the filter for contaminant protection and easily alleviates the use of an outside check valve into certain systems.

We’re Protected

With a 100-micron and 6-micron filter installed on our recirculating fuel system, we are confident that no contaminants within the fuel will affect our electronic fuel injection or wreak damage to our fuel pump. Paitz finished by adding his recommended maintenance schedule.

Fuelab’s “beast” of a filter is the 868 PRO Series Extreme Flow inline filter. With a 6-inch filter length, it can flow a massive 10 gallons-per-minute with -10 AN fitting ends.

“So, people ask me how often I should change the fiberglass filter? For drag racing guys, make it a once-a-season inspection for the filter, plus a thorough cleaning of the stainless filter. But there are so many variables, such as where do you get your fuel? Is it going into a stock tank? Is it E85? Are you straining the fuel before putting it into a cell? These variables should have you considering a tighter inspection and maintenance schedule.”

If you consider the many gallons of fuel that pass through your racing fuel system, keep in mind how quickly particles or even the slightest degradation of your fuel lines can affect your fuel system. Think about these quality filters as a protective component for your fuel system and monitoring devices to inspect what tiny micron-sized “hitchhikers” are corrupting your performance carbs or injection system.